Buy ATEX motors – project planning incl.

In addition to the explosion-proof motors, we also offer project planning for your required drive.

Let us send you a non-binding offer now!

Explosion-proof motors in potentially explosive environments

The prefix ATEX (French abbreviation for ATmosphères EXplosibles) designates as prefix products/devices which can be used in explosive environments.

Potentially explosive environments are everywhere, where combustible dust (dust zones 21 / 22) or explosive gas or vapour-air mixtures (gas zones 1 / 2) can occur in the atmosphere:

- Baker (flour-processing productions such as large bakeries)

- Painter…

- motor vehicle technician

- Plastics processor

- Miller

- Stores (with paints, varnishes, chemicals, wood)

- Liquid gas storage

- Transportation

- Hospitals

- Wood processing companies (e.g. cabinetmakers)

The most important guidelines for explosion protection:

ATEX (EU)

IEC Ex (International Electrotechnical Commission based in Geneva)

NEPSI (China)

Temperature classes (gas)

The effort required to operate an actuator, or the conditions that an actuator must fulfil in order to be able to operate in a explosive environment depends on the classification of the environment.

- T1 with max. surface temperature of 450 °C.

For example when processing- propane gas: 510 °C

- Natural gas: 650 °C

- T2 with max. surface temperature of 300 °C.

For comparison the ignition temperature of- acetylene: 305 °C

- T3 with max. surface temperature of 200 °C

For comparison the ignition temperatures of- petrol 260-450 °C

- Diesel 220 °C

- T4 with max. surface temperature of 135 °C

For comparison the ignition temperatures of- diethyl ether 170 °C

- T5 with max. surface temperature of 100 °C

- T6 with max. surface temperature of 85 °C

For comparison the ignition temperatures of- carbon disulphide 95 °C

Ignition temperature (dust)

In an environment with dusts, the exact ignition temperature of the dusts occurring is decisive. The surface temperature should be some distance below this temperature.

Ex zones

The effort required to operate an actuator or the conditions that an actuator must fulfil to be able to operate in a potentially explosive environment depend on the classification of the environment. This is followed by the designation of the areas/zones according to the occurrence of the potentially explosive atmosphere:

- Zone 0: constantly or over long periods or frequently present.

- zone 1: occasionally present during normal operation.

- Zone 2: during normal operation normally not available or only for a short time.

- Zone 20: constantly or over long periods or frequently present: Zone 0

- Zone 21: occasionally present during normal operation.

- Zone 22: normally not available during normal operation or only for a short time.

You are interested in ATEX motors and our services ?

Since 1993 we are responsible for our further growing customer base. We would be pleased if we could also support you. Please contact us or …

Variants

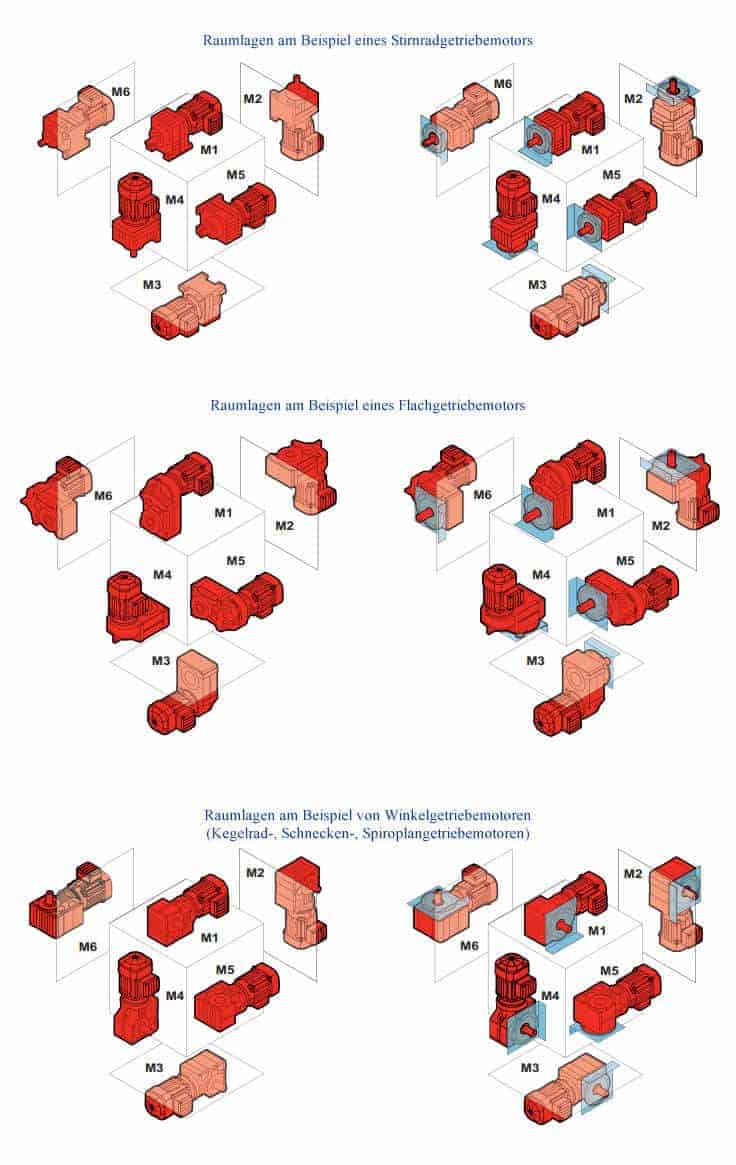

Apart from the fact that gear units and motors can be dimensioned/equipped differently, there are other important properties depending on the use of the gear motor. We will be pleased to advise you!

- Filling level with oil must be ensured. All teeth, rolling bearings, etc. must be immersed in oil by revolutions and completely lubricated.

- The spatial position determines the design: foot, flange or, in a few cases, both.

- Normally, a geared motor cools itself. In exceptional cases, a forced cooling fan must be fitted.

- position terminal box / cable entry plug position

This point again concerns the nature of the operating location. Of course, good accessibility of the cables is desired. The position of the terminal box on the motor and the cable entry should be well planned. - with & without brake (SEW brakes & brake rectifier)

- With & without tacho transmitter (for operating the geared motor by frequency converter)

- With explosion-proof three-phase motors (ATEX) for use in potentially explosive atmospheres (EU Directive 94/9/EC (ATEX), or from 20.04.2016 the EU Directive 2014/34/EU (ATEX))

- temperature sensor

- Aseptic: In some applications such as: food, luxury food and beverage industry, etc. special hygiene regulations must be observed. Gearedvmotor housings must be cleaned regularly and even treated with disinfectant. Therefore, they must be closed and the surface must be painted accordingly. In addition, aseptic gearmotors are larger because they do not require ventilation and the heat can only be dissipated via the larger surface of the housing.

.

Manufacturer of explosion-proof motors

We distribute gear units and geared motors of the following manufacturers:

Lenze

BEGE

Power Transmission

ZAE drive systems